Vacuum Packer

Repairs, Servicing & Sales

in London & Surrey

Protect your product, reduce waste and avoid downtime - with commercial vacuum packer support you can trust.

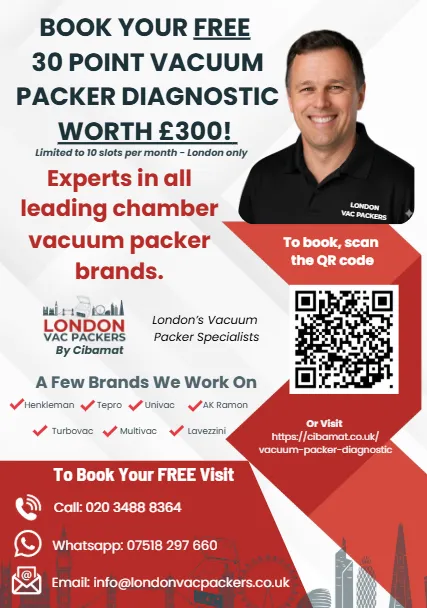

FREE 30 Point Assessment

Get your vacuum packer performing at its best with our free 30-point diagnostic check. Our expert engineers will thoroughly inspect your machine, identify any issues, and provide a detailed performance report - all at no cost. It’s a quick, no-obligation way to keep your

equipment in top shape and see how our service can help you save time, money, and downtime.

Does Your Vac Packer Need Servicing?

Spotting the early warning signs can save you from expensive breakdowns and ruined product runs. If your vac packer is getting noisier, seals

are inconsistent, or cycles seem slower than they used to be, it may be time for a service. Routine maintenance keeps your machine efficient,

protects seal integrity, and helps you plan repairs on your terms rather than in an emergency.

Download our handy checklist PDF below to quickly assess your vac packer and decide whether it’s due a professional inspection.

Upgrade & Save!

Upgrade your vacuum packer without the full cost of a brand-new machine! Trade in your old vac packer with us, and we'll use this as a deposit towards the cost of a state-of-the-art Henkelman Jumbo 42! This smart switch delivers faster cycles, superior seals, and durable construction perfect for demanding food production, helping you minimise downtime and extend product freshness. Contact us to value your trade-in and unlock your savings.

Work With Us

Do you have hands-on experience servicing, maintaining, or repairing vacuum packers? We'd love to hear from you!

FAQs

How does vacuum packaging help in food preservation?

Vacuum packing helps preserve food by removing most of the air (especially oxygen) around it, then sealing it in an airtight package, which slows spoilage and quality loss.

Are London Vac Packers machines compliant with food safety regulations?

Yes, all our machines comply with the latest food safety regulations and are safe for direct food contact.

What signs tell me my vacuum packer needs attention?

Common warning signs include longer vacuum cycles, weak or incomplete seals, unusual noises, oil contamination or inconsistent results in cooked or stored food. If you notice any of these, it is best to book an inspection before the machine fails during service.

Why is regular servicing of my vacuum packer important?

Regular servicing helps maintain vacuum strength, seal quality and pump efficiency, which directly affects shelf life, appearance and sous‑vide results. Proactive maintenance also reduces unexpected breakdowns and extends the working life of your equipment, saving you money over time.

How often should vacuum packaging equipment be serviced?

We recommend a general service check-up at least once a year, depending on use frequency.

Do you offer maintenance plans or regular service visits?

Planned maintenance visits can be arranged to suit your operation, from annual checks to more frequent inspections for high‑volume sites. Regular plans make budgeting easier and help catch issues before they interrupt service.